As machining basics go, understanding the difference between turning and milling is vital. While turning and milling are two familiar machining processes which both remove material from a workpiece using a cutting tool; they use different and distinct methods to achieve this, and with different outcomes too.

Put simply:

• When turning, the part moves and the tool stays still

• When milling, the part stays still and it’s the tool that moves

Turning and milling have different advantages, as well as capability in terms of part complexity and geometry. In addition, they both produce different geometrical surfaces, so it’s essential to understand which method will achieve your particular part specification when you're buying CNC machining.

Turning

Turning is a machining process carried out by a lathe and it’s a relatively simple machine. In a turning machine there’s a chuck to hold the workpiece, with the lathe spinning this workpiece as the cutting tool moves across it. It has to be able to spin on its axis, but the cutting tools work across only two axes of motion in order to achieve exact depth, width and cut precision.

During turning, the cutting tool remains in continuous contact with the workpiece during the entire machining operation.

While using a turning machine is often cheaper due it’s simplicity, as well as the fact that it uses cheaper feedstock (bar is easier to make than billet), the shapes you can create using turning are limited by its nature. Turning reduces the diameter of a part, so parts machined and produced by turning must be cylindrical. This can include basic rings through to more complex curved shapes and cones.

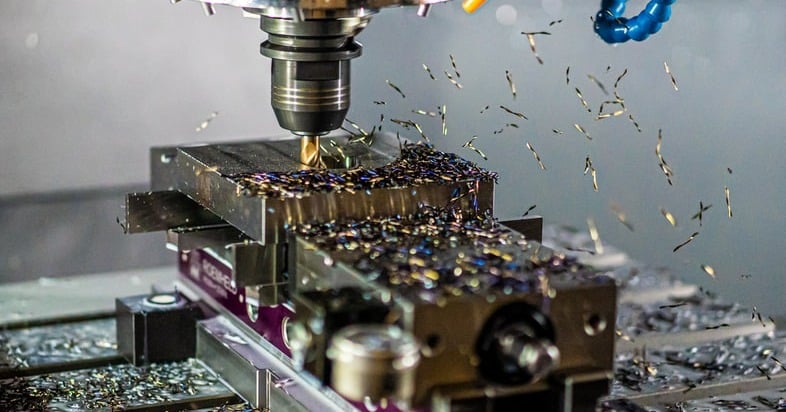

Milling

Milling produces parts with mainly flat surfaces. Milling as a technique uses rotating cutters to remove material, unlike turning where the tool remains still. Milling uses intermittent cutting, where the tool continuously engages, then disengages during the machining process. Milling machines can have more than one cutting tool working on the piece at one time, making it the best choice if the part specification needs any off-centre or angled machining.

Milling can create more complex shapes compared to turning. This is because a milling machine has up to 5 axes of movement to manage- 3 linear ones in the X, Y and Z planes, as well as two rotational axes.

This greater number of axes involved in milling also allows you to cut down on the total cycle time required by eliminating the need to remove and reset the part in a different orientation, making it a quicker process. This reduced cycle time helps to machine parts faster - always a key consideration from a buying perspective.

One important thing to remember is that just because you can use a 5 axis-machine, doesn’t always mean you should. For less complex parts or small batches, it can often be more effective, both in lead time and cost to use a simple 3 or 4 axis machine.

Conclusion

Turning and milling are both subtractive machining process, but they have distinctly different outcomes to your machined part. As a buyer, understanding the differences, as well as the advantages and limitations of both will ensure you choose the best machining method for your part’s complexity and specification.

From machining basics through to detailing some great questions to ask a potential new supplier, our Machining Buyer’s Guide is a great introduction to choosing and working with a machining supplier.

Get in touch

Get in touch