Casting large components such as giga casting requires a complete shift in terms of approach; both by engineers and automotive manufacturers.

While giga casting offers huge opportunities for sustainable, cost effective automotive manufacturing, there are also a number of challenges to overcome during the process.

In this blog, we'll discuss some of these key challenges; covering size, shape, material composition and method.

Giga casting challenge 1: Size of the casting

The change in scale of giga castings is not incremental - it's a step change for the automotive industry. The size and scale of giga castings mean a different approach is required, across the entire manufacturing process. This includes considerations such as:

- More physical manufacturing space is required

- More sand is needed for a giga casting that can weigh over 7 tonnes

- Different and bigger infrastructure is required to handle the casting

- More space is needed to finish and machine the giga casting

- The logistics of the supply chain pre and post production will also require a different approach compared to traditional cast components

Giga casting challenge 2: Size of the casting

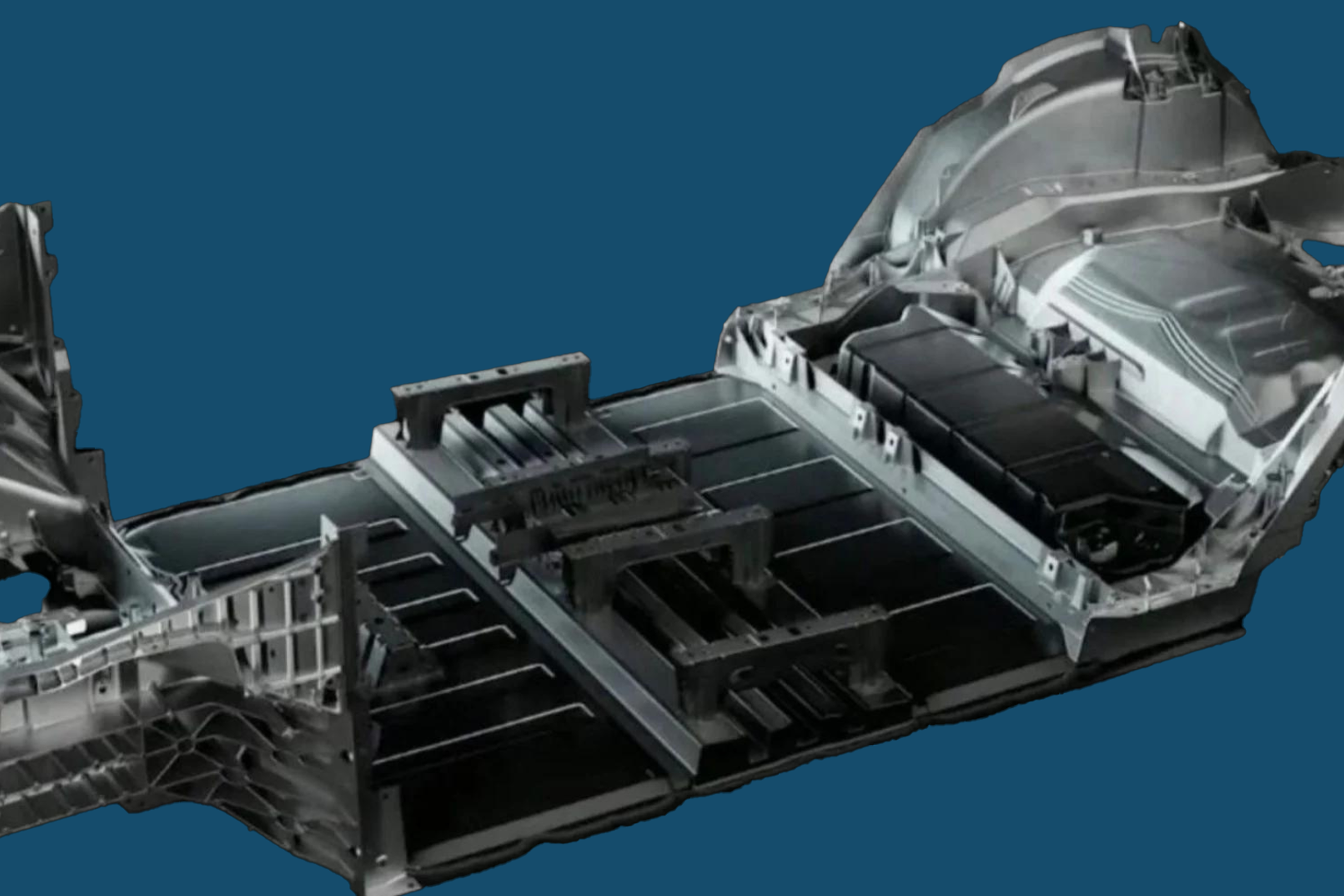

Giga castings have longer sections and thinner walls than traditionally cast components. The length of a single giga casting can reach up to 1.5m, requiring different handling. Designing effective runner and feeder systems to control the rate of solidification in the giga casting is vital. Longer, structural parts will also require different machining processes and equipment.

Giga casting challenge 3: Material properties of the casting

Giga castings have different material property and material composition requirements, both to allow the casting process and to achieve the desired final properties for the component. Giga castings are required to flex and recover, requiring higher ductility and elongation compared to complex prismatic parts.

Giga castings also need less strength to reduce brittleness. Aluminium-silicon alloys can be developed to match these required properties at the prototyping stage, delivering robustness and elongation. Aluminium alloys allow thin-walled castings to be made as low as 2.8mm, reducing the inherent mass volume of the part.

Giga casting Challenge 4: Method of casting

Giga casting needs different approaches in design, heat treatment, machining and handling. This is creating a huge shift from traditional automotive manufacturing. Giga castings require relatively fixed design architecture compared to traditional vehicle manufacturing.

While this makes changes in the process difficult, this does drive discipline in the giga casting process- providing a 'hard point' which is important in automotive manufacturing.

Giga castings require a fundamental shift in engineering approach. Innovation is essential, using knowledge and casting expertise to approach things differently.

To find out more about giga casting, and the role of sand casting in the process, download our free eBook 'Prototyping Giga Castings with Sand Casting'.

Get in touch

Get in touch