In this series of articles, GW celebrates great products that use great castings, and it is the turn of the Tesla Giga Casting.

Using the IDRA Group's Giga Press, Elon Musk has said that Tesla are "trying to make full-size cars in the same way that toy cars are made". But this certainly isn't play time. Tesla continues to install Giga Presses across its global operations as it seeks to change the way cars are manufactured.

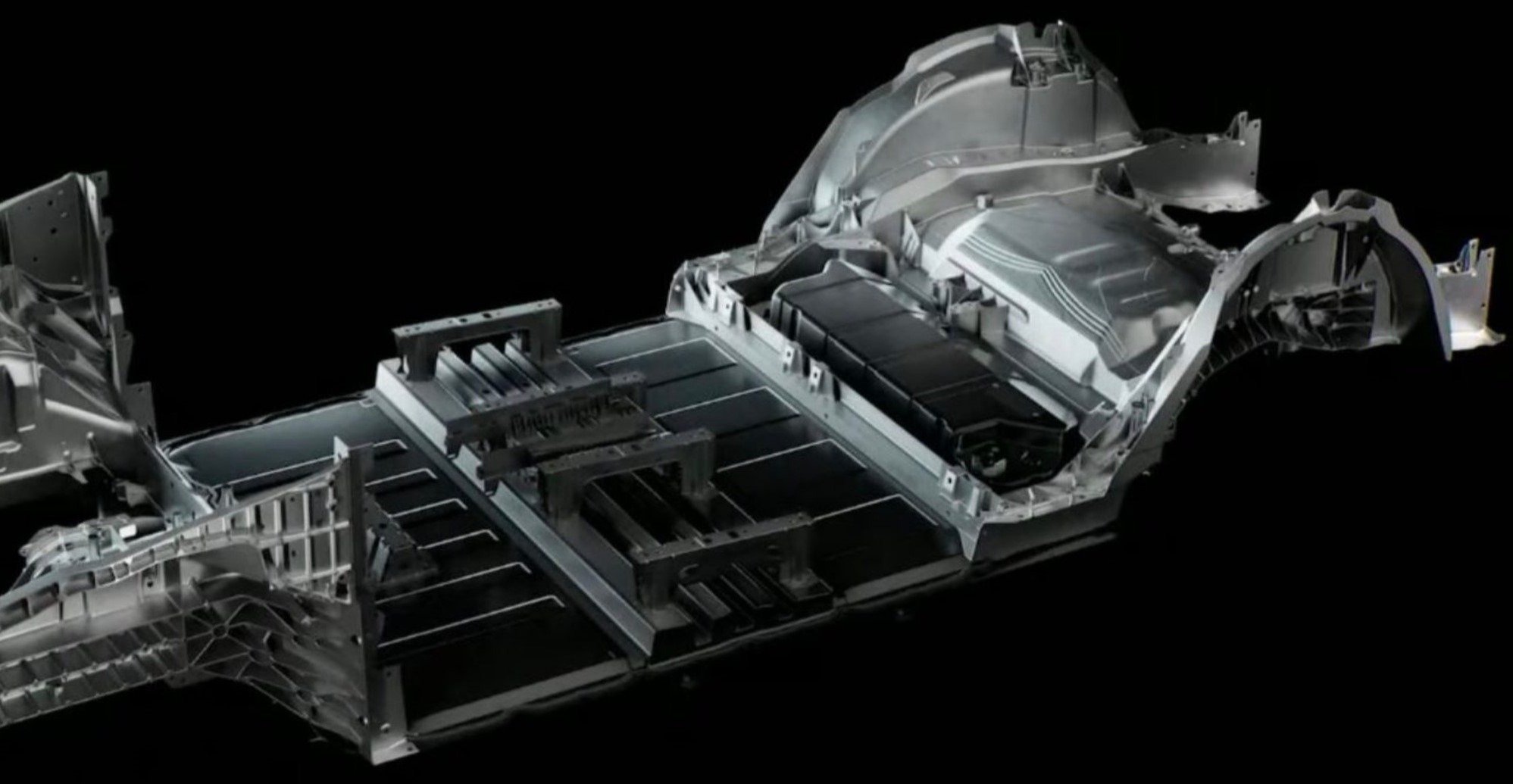

370 fewer parts, 10% mass reduction, 14% range increase.

Well that's a pretty good list of step change benefits. All achieved by developing a new alloy and turning a not-so-humble aluminium casting in to a game changer for the design of car structures. Who would have thought of casting half a car in one go?

It's the sort of step change that Cosworth did 40 years ago with a new casting process. It also happens to be the sort of technical challenge that Grainger and Worrall takes on all the time in sand casting technology - material development, part count reduction, vehicle light-weighting, dimensional conformance.

This shows what you can do when you understand the fundamentals of a manufacturing process and then challenge the accepted boundaries.

At Grainger and Worrall, we have been developing prototype sand castings to mimic die-cast parts like those used in the Giga Press. Aluminium-silicon alloys can be created to match properties achieved in high pressure die casting for high-volume production. This allows mitigation of heat transfer in sand casting moulds, enabling controlled solidification rates without the need for heat treatment. This is analogous to the high cooling rates of die casting, producing sand cast prototypes with the required properties of tensile strength, yield strength and elongation.

Read more about how sand casting can be used to prototype giga-cast parts.

Learn about controlling mechanical and material properties with alloy selection.

Find out more about the sand casting process

Elon Musk is reshaping the art of the possible through casting innovation. Now where have we heard that before?

Take a look at this 7 minute clip at his outdoor unveiling in 2020 where he explains the parallels with aircraft wing design, the advances in materials, and how the battery tray is now an integral part of the structure of the vehicle, ""I think that long term any cars that do not take this architecture will not be competitive".

If you'd like to know more about how the sand casting process can help drive automotive innovation read our ebook, The Basics of the Sand Casting Process.

Get in touch

Get in touch